Solutions

Let's start work together

Kruiswijk 4, 1761 AR

Anna Paulowna, NL

+316 833 320 78

t.pankras@hemp-drying.com

Hemp Flower Drying

The hemp flower and leaves, as a source of cannabinoids and terpenes for extracts or whole flower applications is a valuable source material. After drying at low temperature it retains most of its components with minimal los of its value. We do this in a box or container installation, under control of our ABC-software.

How does it work?

Retain the maximum amount of cannabinoids and terpenes with a controlled and precise drying process. Our meticulous approach to hemp flower drying involves the use of conditioned drying techniques at consistently low temperatures. By employing this method, we ensure that the delicate compounds and aroma of the flowers remain intact, ultimately allowing us to maximize the value of our premium hemp products.

Cannabinoid Purpose Crop

- Greenhouse-grown or outside grown

- The fresh flowers are bucked or trimmed

- The hemp flowers are deposited in our special drying boxes

Hemp Flower

Cultivate hemp flower with dual potential! Optimize your harvest for both industrial and cannabinoid purposes. Maximize the versatility of your crop with our expert guidance.

Dual Purpose Crop

- The hemp flower is separated from the plant

- Deposited in a container trailing behind the combine

- Stalks are cut and left on the field for later harvesting

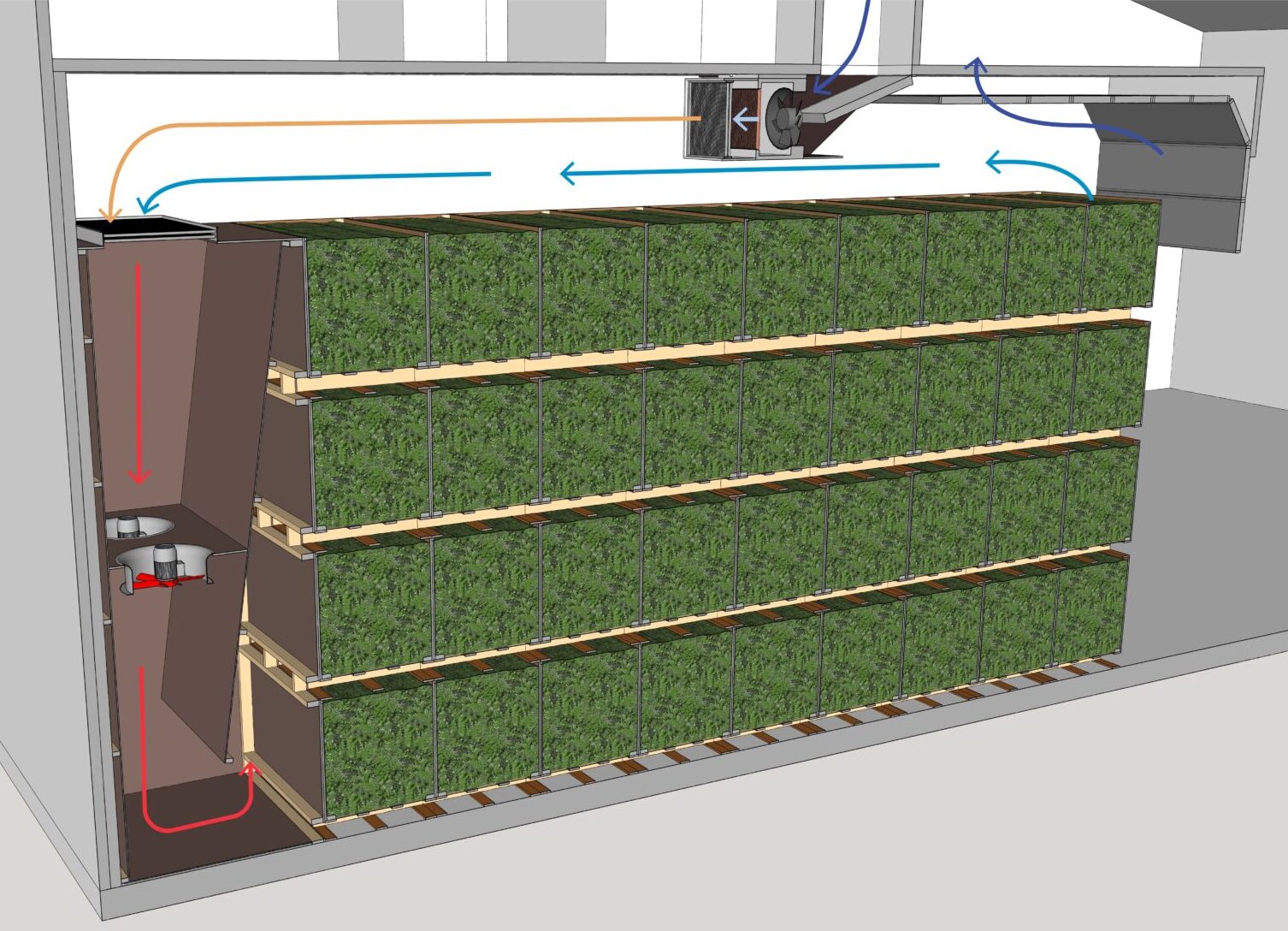

Conditioned Drying Process

Discover our advanced hemp flower drying system designed to maximize quality and efficiency. Below, we highlight key features of our system, including a controlled drying environment, versatile drying methods, and precise preservation techniques

Optimized Drying Environment

The drying cell, or container, is conditioned with dehumidified air, allowing for high drying capacity at low temperatures.

Flexible Drying Methods

The installation is equipped with boxes filled with hemp flowers, including options for boxes with drawers or bulk filling.

Gradual Preservation

Hemp flowers undergo a five-stage drying process using air with a maximum temperature of 20°C to preserve cannabinoids and terpenes effectively.

Working Process

Our hemp drying process is a seamless journey designed to deliver optimal results for your hemp crop. Here’s a brief overview of the three essential steps:

Consultation

In an open conversation, we discuss your drying or retting need. We will advise you on the best installation for your situation.

Design and Work

From this point we will bring your installation from imagination, to technical design, to reality. The installation will be installed on site and is ready for use.

Complete & Maintenance

We will help you get familiar with your new installation and explain proper use and maintenance.